Reverse Engineering

Reverse engineering includes any activity to determine how a product works, or to learn the ideas and technology that were originally used to develop the product. Reverse engineering is a systematic approach for analyzing the design of existing devices or systems. It can be used either to study the design process, or as an initial step in the redesign process, in order to do any of the following:

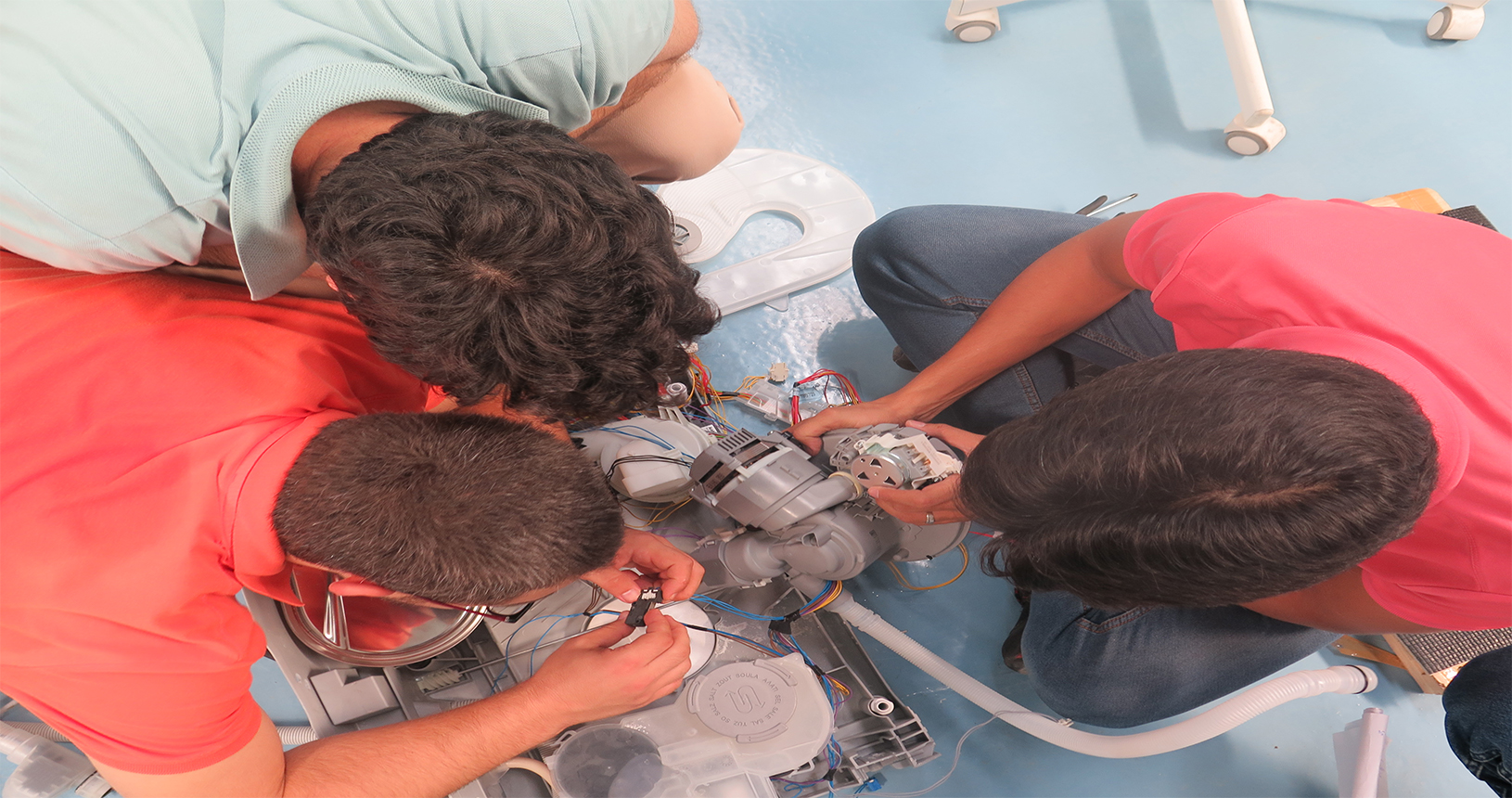

– Observe and assess the mechanisms that make the device work

– Dissect and study the inner workings of a mechanical device

– Develop the part or product geometry in a CAD model from the actual part or product

– Compare the actual device to your observations and suggest improvements

Reverse engineering may also be necessary if alternative methods of obtaining technical data are more costly than the actual reverse engineering process.

Reverse engineering initiates the redesign process, wherein a product is observed, disassembled, analyzed, tested, “experienced,” and documented in terms of its functionality, form, physical principles, manufacturability, and ability to be assembled. The intent of the reverse engineering process is to fully understand and represent the current instantiation of a product.

In Mudatech, reverse engineering is done by highly experienced experts and the results are used to develop products suitable for different market needs.